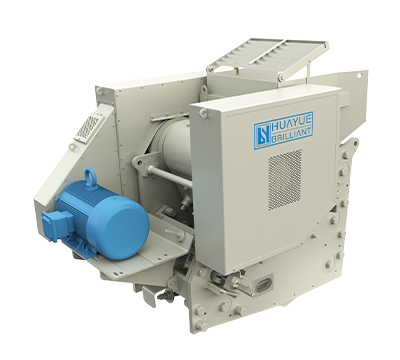

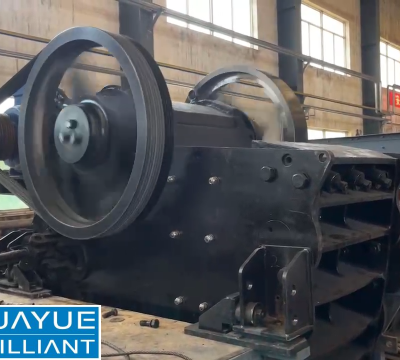

C series jaw crusher is developed and applied widely in mines, quarries, road construction, building material, highway, railway,water conservancy and other industrial. The core of Huayue C Series jaw crusher is a pinned and bolted, non-welded frame construction that provides excellent fatigue strength. All the frame components are casted using an alloy developed in-house especially for jaw crushers. In addition to solid casting, C series jaw crushers' frame has a cellular, so called honeycomb structure that, like in nature, has proven to be stronger and more durable.

Huayue SC Series jaw crushers have an aggressive motion of the pitman and long stroke in the bottom of the cavity.A larger feed opening increases material intake and ensures that the rocks enter the jaw crusher's cavity without restrictions. A steeper nip angle decreases operating costs by reducing wear on jaw dies and speeds up material flow down in the cavity. Jaw crushers are designed modular to save time and installation costs. They can be installed within a few days, minimizing on-site engineering and fabrication.

- Pinned and bolted, non-welded frame construction

- Outstanding fatigue strength

- Excellence in casting engineering

- Premium-quality components

- Easy to install in place of an existing crusher

- Option for remote monitoring, automation and settings adjustment

- Possibility to transport to the site in pieces

1.Stone material

2.Mine(ground surface and downhole)

3.Waste recovery(concrete and bitumen)

4.Industrial(slag and anode)

简体中文

简体中文 ENGLISH

ENGLISH

HOME

HOME